A Compact Powerhouse for Slow-Speed, High-Torque Applications

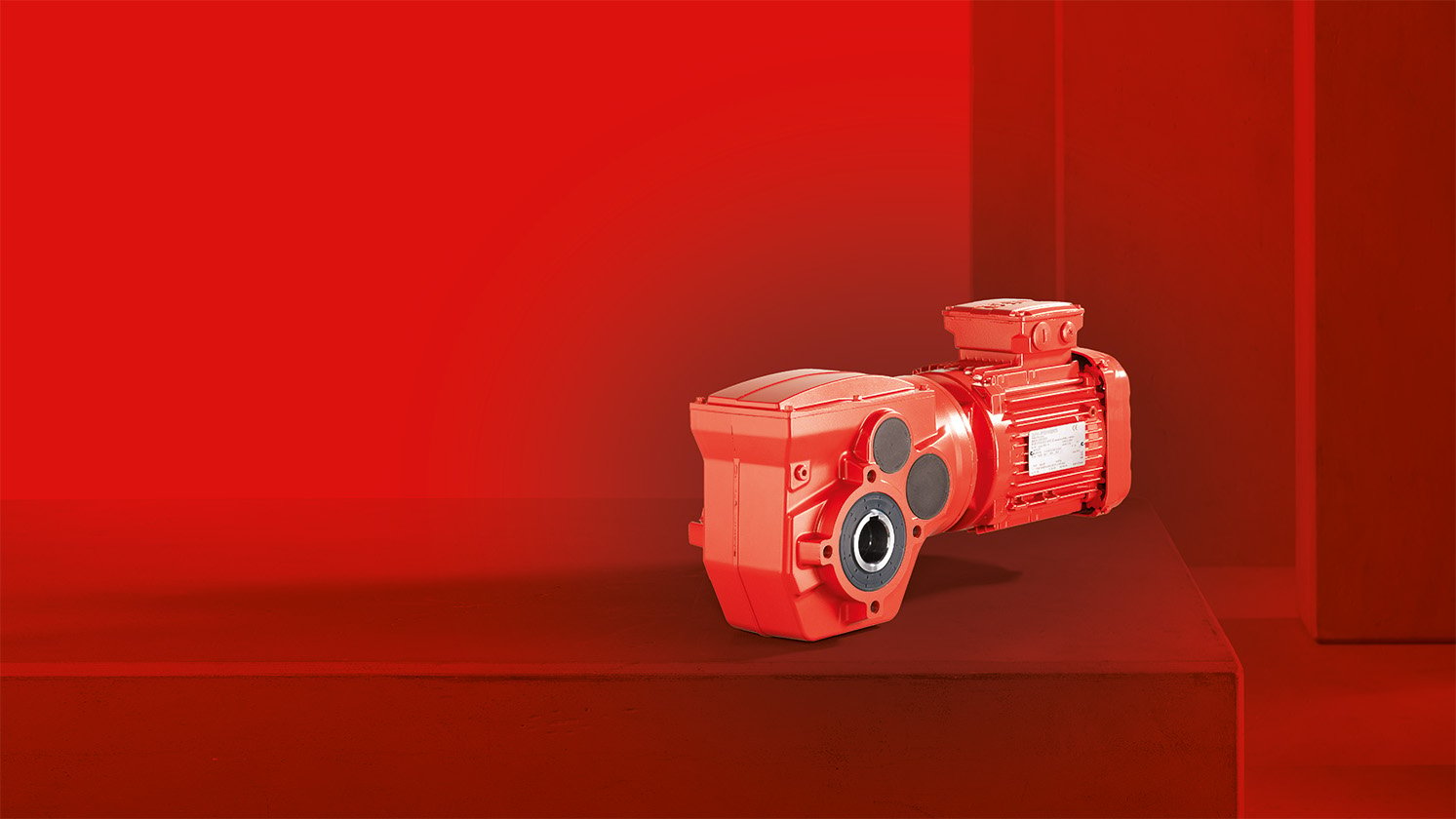

When it comes to motion control solutions that deliver performance, reliability, and design flexibility, SEW-EURODRIVE is a trusted partner to OEMs and machine builders around the world. One of our newer innovations, the W..9HG SPIROPLAN right-angle gear unit, reinforces that reputation by combining high gear reduction, compact size, and robust torque handling in a form factor that stands out in the market.

Designed for applications that demand very slow speeds, smooth operation, and maximum torque density, the W..9HG series is more than a gear unit. It's a smart, space-saving solution that overcomes the limitations of traditional compound gear assemblies, worm drives, and large helical bevel units.

Built for the Demands of Modern Equipment

Whether you're designing a conveyor system for intralogistics, a hygienic mixer for food processing, or a high-torque drive in a compact machine enclosure, the W..9HG delivers the performance you need without compromise.

With gear ratios greater than 2,000 and output torque capabilities up to 600 Nm, the W..9HG series provides the high reduction required for extremely low output speeds—but in a compact, right-angle housing that simplifies system design and integration.

This is achieved using a three-stage design: the first stage is our proven SPIROPLAN gearing, which ensures right-angle operation and wear-free performance, while the second and third stages use helical gearing to provide high overall gear ratios. This combination allows for finely stepped ratios and smooth, quiet motion.

Compact. Quiet. Capable.

Traditional solutions for high-ratio applications often rely on bulky compound gearboxes or worm gear drives. These designs may be large, heavy, or inefficient. The W..9HG turns this challenge on its head.

Compared to traditional compound gear units, the W..9HG is up to 27% shorter and 34% lighter, without sacrificing output torque or durability. This smaller footprint not only frees up space in machine designs but also simplifies handling and installation, making it a favorite among machine builders and integrators.

And when it comes to acoustics, SPIROPLAN® gearing truly shines. With optimized tooth geometry and low internal friction, the W..9HG runs significantly quieter than worm gear equivalents or bevel-helical configurations. This makes it especially attractive for applications in noise-sensitive environments like food production, packaging lines, or cleanroom equipment.

Technical Advantages that Matter

- High Gear Ratio Range: Ratios from over 200:1 to over 2400:1 in a three-stage right-angle gearbox

- Torque Range: Up to 600 Nm across sizes W..29HG through W..59HG

- Lightweight Housing: Aluminum construction for reduced mass and easier integration

- Universal Motor Interface: Compatible with SEW-EURODRIVE motor sizes DR..63 and DR..71, streamlining system integration

- SPIROPLAN® Gearing: Durable, wear-free first stage provides smooth, quiet, and efficient right-angle motion

- Service Simplified: Standardized oils and modular parts make maintenance and servicing quick and easy

In addition, the use of SEW GearOil Poly 460 W under standard operating conditions ensures excellent thermal performance and long service intervals, even in demanding duty cycles.

Ideal Applications and Industries

The W..9HG series was engineered to solve problems in real-world applications where space is limited, torque is critical, and performance must be reliable day in and day out. Here's where the W..9HG truly excels:

Mixers and Agitators

Used in the baking, food processing, or chemical industries, these systems require high torque at low speed, often in clean environments. The W..9HG’s smooth motion and quiet operation make it ideal for mixing dough, blending ingredients, or agitating fluids without excessive wear or noise.

Conveyors

Whether it's a chip conveyor in machining or a slow-speed belt in packaging, conveyors benefit from the high reduction and compact size of the W..9HG. The unit delivers reliable, low-speed motion in a small package that doesn't get in the way of mechanical layouts.

Food & Beverage Equipment

Cleanability, quiet operation, and reliable performance are key in these environments. The W..9HG delivers all three, with a sealed, compact design and the ability to operate efficiently at very low speeds.

Intralogistics

Automated warehouse and material handling systems often require gear units that can be integrated into tight spaces, maintain precise speed control, and operate with low noise. The W..9HG checks all the boxes, while also supporting lightweight system design.

Screw Conveyors and Wash Systems

In rugged processing environments where slow, continuous motion is needed, the W..9HG offers a high-torque solution that withstands the elements and resists wear over long service periods.

Why W..9HG is a Better Alternative

When compared to common market alternatives, the W..9HG has several key advantages:

- Versus Compound Helical or Bevel Gear Units: The W..9HG provides similar or better gear ratios in a smaller and lighter format, with easier motor integration and less mechanical complexity.

- Versus Worm Gear Units: Unlike worm gearing, SPIROPLAN® delivers higher mechanical efficiency, quieter operation, and longer wear life. No compromise on performance.

- Versus Custom Shaft Designs: The universal flange interface and compatibility with SEW-EURODRIVE motors simplify specification and reduce engineering overhead for OEMs.

All of this translates into real-world savings on space, weight, energy use, and time—not to mention a lower total cost of ownership.

Backed by SEW-EURODRIVE’s Global Support

As with every product in our portfolio, the W..9HG SPIROPLAN® gear unit is supported by SEW-EURODRIVE’s global network of application engineers, service experts, and local assembly centers. Whether you're designing a new line or retrofitting an existing system, our team is ready to help configure, install, and support your drive solution from start to finish.

Explore the Possibilities

The W..9HG series is more than a gear unit—it's a smarter approach to slow-speed, high-torque motion in a right-angle gear format. And it's only from SEW-EURODRIVE.

About SEW-EURODRIVE

Founded in 1931 in Bruchsal, Germany, SEW-EURODRIVE is a global leader in Industrial Automation, with operations in over 50 countries, 17 manufacturing plants, 92 assembly facilities, and more than 21,000 employees. The company holds over 1,000 patents, continuously driving technological advancements in gearmotors, frequency inverters, servo drives, and Industry 4.0 solutions.SEW-EURODRIVE provides engineered solutions in countless industries, including automotive, food & beverage, pharmaceuticals, mining, steel, logistics, energy, and more, providing customized automation solutions that enhance efficiency, productivity, and sustainability. Despite its global reach, SEW-EURODRIVE remains family-owned, ensuring long-term vision, strong values, and a commitment to excellence.

SEW-EURODRIVE ... Driving the world. Find your local rep today!

SEW-EURODRIVE, Inc.

220 Finch Road

Wellford, SC 29385

(P): (864) 439-7537

cslyman@seweurodrive.com

www.seweurodrive.com