Case Studies & White Papers

NEW CASE STUDY | Recurring gearbox failures were causing costly downtime in a critical mixer operation. SEW‑EURODRIVE replaced a multi-vendor legacy drivetrain with a single integrated gearmotor and VFD from a single source, eliminating failures and simplifying maintenance.

NEW CASE STUDY | A failed wastewater aerator threatened major regulatory risk and costly downtime for Orange County Utilities. With a 24-week OEM lead time and no dimensional drawings, the pressure was on.

NEW CASE STUDY | Logan Aluminum encountered a critical bottleneck in its pusher furnace drive system, limiting cycle time & throughput. SEW responded with a smarter solution that increased drive speed and throughput by 5X.

WHITE PAPER | Learn why it can be a good idea to operate gearmotors above 60Hz. Through a common example, we will show you how to select the proper gearmotor that will significantly enhance performance.

CASE STUDY | Replacing belts and pulleys with SEW-EURODRIVE's MC Series units create significant system efficiencies and long-term reliability for Mandarin Wastewater Treatment Plant.

WHITE PAPER | Learn more about the productivity and efficiency gains of outfitting a sawmill’s resaw line with VFDs, Ethernet, and other automated electromechanical systems.

CASE STUDY | X3K/KF97, Cement Production - A cement plant replaced a dated chain-and sprocket drives with an SEW direct-coupled gearbox and motor system, resulting in multiple efficiencies.

CASE STUDY | MOVIGEAR, Beverage Production - The soft drink bottling plant is focused on reducing CO2 emissions as well as energy costs. MOVIGEAR® drive systems provided unexpectedly high energy efficiency for transporting PET bottles and packaging units.

CASE STUDY | MOVIGEAR, DRC, Baggage Handling System - Terminal 4 in the LAX airport needed a thorough upgrade to the baggage handling system (BHS) for both American Airlines and TSA operations. Complying with strict California Title 24 energy standards and reducing the load on the existing power station were both high priorities.

CASE STUDY | MOVITRANS®, Amusement Park - The oldest people mover at Europa-Park, the historic Panorama Train, is saying goodbye to the internal combustion engine. The switch to environmentally friendly electrification is taking place at the most modern level.

CASE STUDY | X3 KS 200, Amusement Park - Industrial gear units and comprehensive service for one of Europe's most state-of-the-art roller coasters – "The Oath of KÄRNAN" promises HANSA-PARK visitors an adrenalin-fueled XXL experience, with SEW‑EURODRIVE working behind the scenes to ensure their safety.

CASE STUDY | MOVIGEAR, Baggage Handling System - Gatwick Airport is experiencing constantly rising passenger numbers. The existing luggage transportation systems in the North and South Terminal were expanded in order to cope with this increase.

CASE STUDY | Girth Gears, Cement Production - CEMEX, a major player in the cement industry, has opted for drive technology from SEW-EURODRIVE at its cement plant. Highly resilient girth gears and pinions were used to modernize two ball mills.

CASE STUDY | XP, Sugar Production - For the sugar industry, powerful drive technology is the key to a smooth processing of sugar cane. Sugar cane is mainly cultivated in the Caribbean and in the USA. Heat and dirt are the major challenges in these areas. The requirements imposed on gear units are high.

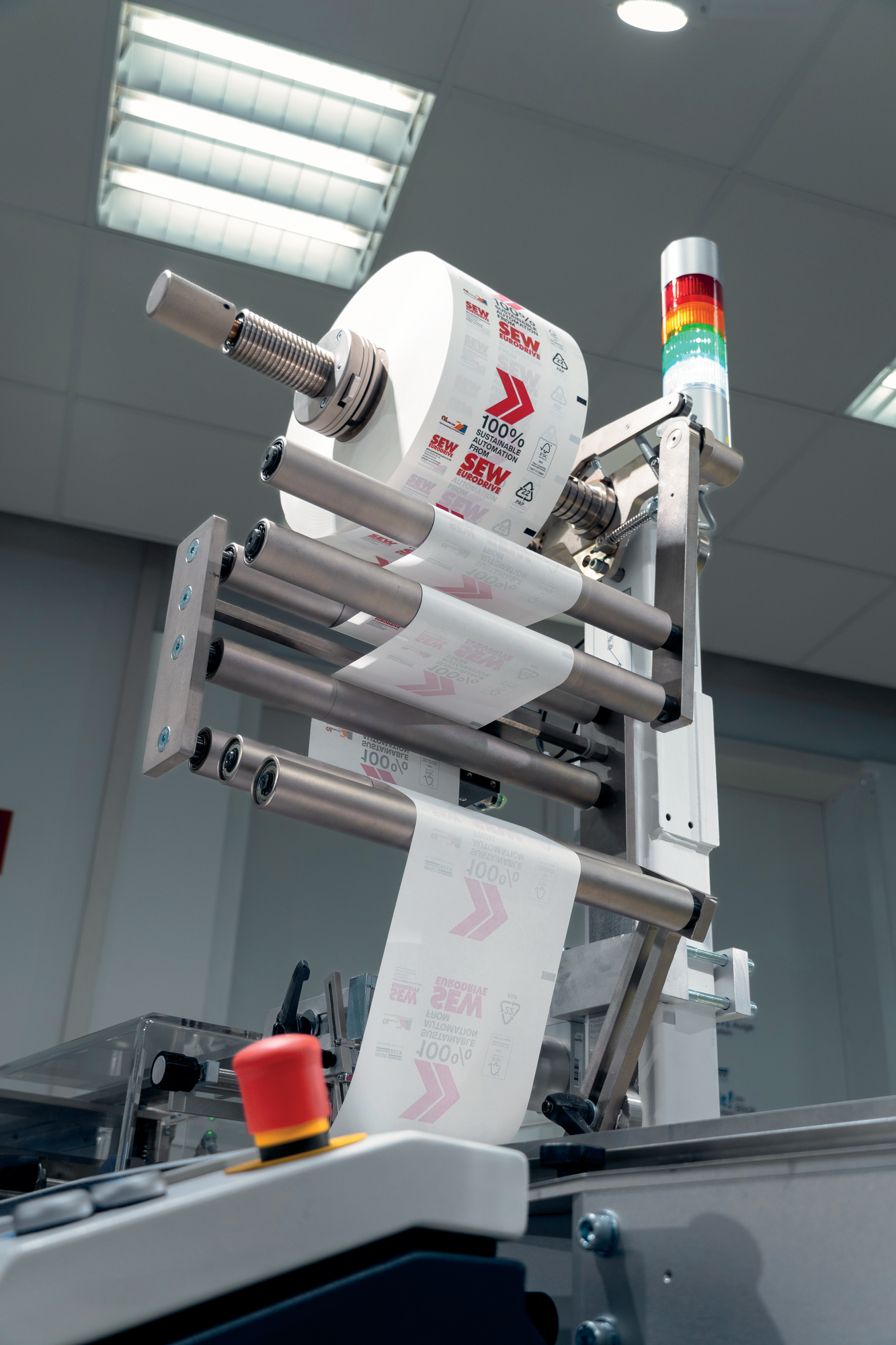

CASE STUDY | Hugo Beck has developed the “flowpack R” horizontal FFS machine with SEW-EURODRIVE, highlighted by compressed air-free technologies – completely automated to achieve maximum flexibility.

/Case%20Studies/26-01_Washington%20Mills_9MD1514-0126/Images/SEW_AFTER_9MD1514_3_1200x628.png)

/Case%20Studies/26-01_Orange%20County_9MD1511-0126/Images/SEW_AFTER_Orange-County_9MD1511-3.jpg)

/Case%20Studies/26-01_Logan%20Aluminum_9MD1512-0126/Images/SEW_AFTER_9MD1512_Logan-Aluminum-1.png)

/White%20Papers/2024_08_WP%20-%20Sawmill/2024_08_WP1000-Sawmill_Install_1200x628.jpg)

/case-study-gatwick-movigear-impression1-800x600.webp)

/girth-gear-with-protective-cover-799x400-2x.webp)

/sugar-mill-new-unit-559x315.webp)